Soft Starter reduces electrical and mechanical motor stress by controlling inrush current, and starts a motor more softly and safely. In addition, it monitors the state of motor and protects it at ordinary times.

| Input | inputvoltage | 3 Pahse, 230~500V, 690V(-20%~+15%) |

|---|---|---|

| Supply frequency | 47~62Hz | |

| Control votage | 220~230V(±10%) | |

| Output | Output voltage | 0~100% Supply voltage |

| Output frequency | 47~62Hz | |

| Efficiency [at full load] | >99% | |

| Environmental Conditions |

Ambient temperature | -10℃ ~ +45℃ |

| Altitude losses | Below 3,000mnote1 | |

| Ambient humidity | Less 95%(non-condensing) | |

| Enclosure | IP20 | |

| Serial Communications |

Standard | RS232/485, Modbus |

| Option | Profibus, DeviceNet | |

| Motor Protections |

Input phase missing, High current, Low input voltage, Starting current limit, Ortor locked, Moter overload(thermal model), Undefload, Phase unbalance, Moter overtemperature(PTC, normal status 150R-2k7), Shearpin current |

|

| Protections | Thyristor fault, SS7 over temperature | |

| Sources Control | Localvia keypad, Remotevia digital inputs, Remotevia Serial Conmmunications (Mobus, RS232/485) |

|

*note1) More 1,000m, 1% derating each 100m

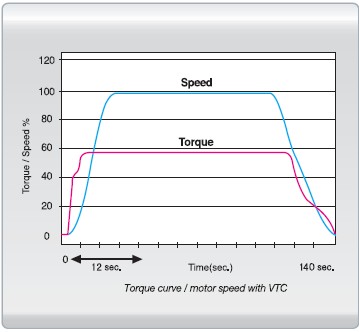

| Adjustmentsnote2 | Torque surge, Initial torque, Initial torque time, Acceleration time Current limit : 1~in, Overload : 0.8~1.2In, Overload slope : 0~10, Deceleration time / Freewheel stop, DC braking, Slow Speed(1/7 fundamental frequency), Dual setting Number of starts allowde, Torque contriol, Water hammer surge control stop |

|---|---|

| Input Signals | 2 analoque input, 0-20mA or 4-20mA, 0-10V |

| 5 configurable digital inputs | |

| 1 PTC input | |

| Output Signals | 1 analogue output 0-20mA or 4-20mA |

| 3 changeover output relats (250VAC, 10A non inductive) | |

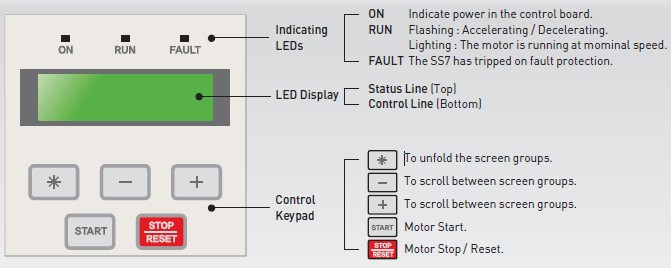

| Display Information |

Phase current, Supply voltage, Relays status, Digital inputs/ PTC status, Analogue inputs value, Analogue output value, Overload status, Motor supply frquency, Moter power factor, Developed power, Motor shaft torque, Fault history (5 most recent faults) |

| LED'sIndications | LED1 (green) : Voltage present on control board |

| LED2 (orange) : Blinking, Motor accelerating/ decelerating On, moter running |

|

| LED3 (red) : Fault present |

*note2) For additional information consult the technical manual